After two batches of farmhouse cheddar, I was ready for the next step in technical difficulty, stirred-curd cheddar. Again I was working from the instructions in Ricki Carroll’s book Home Cheese Making. As reflected in the name, the biggest change in this vs. farmhouse cheddar is that the curd is held at 100 degrees and stirred for an hour after the whey is drained off. This step removes more whey from the cheese, which was noticeably drier than the farmhouse cheddars.

When I was in the middle of making this cheese, I became concerned about how much salt to add. The recipe said 2 Tbs. of cheese salt, but given the different densities of available non-iodized salt, it was unclear how much salt I should add. A general rule of thumb is that the salt should be 2% of the weight of the curds, but I did not weigh the curds and I knew some more whey would be released as I continued to cook and stir the curds. I ultimately added 22 g. of salt at first (2 Tbs. Morton’s kosher), tasted the curds and decided to add another 11 g (1 Tbs. Morton’s kosher). In a few months I will know how well I judged this.

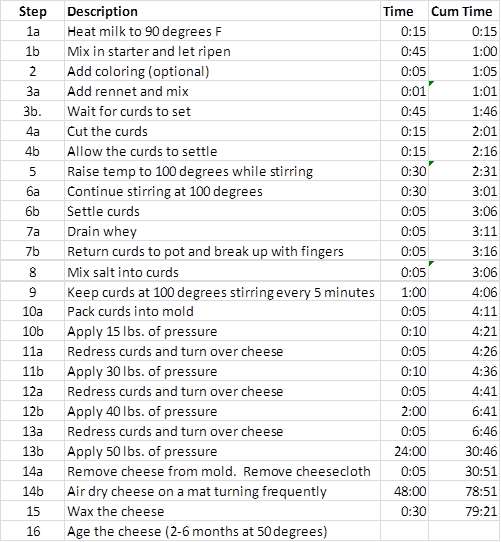

Here is a timeline with a summary of the steps

For the first time, I sterilized my utensils in boiling water in the large pot in which I would heat the milk.

I also used a Gavin Webber idea of heating the milk initially in a double boiler, of my cheese pot on top of a smaller pot. This is a little unstable and needs to be monitored, but it does allow the heat to be easily controlled. After the initial heating, I kept the milk at temperature with the sous-vide wand in the green plastic box. When I was raising the temperature to 100, I kept the water bath at 110. Once I had the curds at 100 degrees, I reduced the temperature of the water bath to 100 as well.